Amidst the complex machinery and intricate processes of industry, one paramount concern rises above all: safety. Within this realm of vital importance, safety relief valves emerge as unsung heroes, diligently guarding against potential hazards. These indispensable components serve a crucial purpose, ensuring the seamless operation of various systems while standing as bulwarks against catastrophic failures. Let’s venture into the fascinating world of safety relief valves, unraveling their significance and understanding their pivotal role in ensuring safety within the industrial domain.

The Essence of Safety Relief Valves

Safety relief valves are mechanical devices designed to control pressure within a system by releasing excess pressure. They serve as a last line of defense against overpressure situations, preventing equipment damage, environmental hazards, and, most importantly, ensuring the safety of personnel.

Anatomy and Functionality

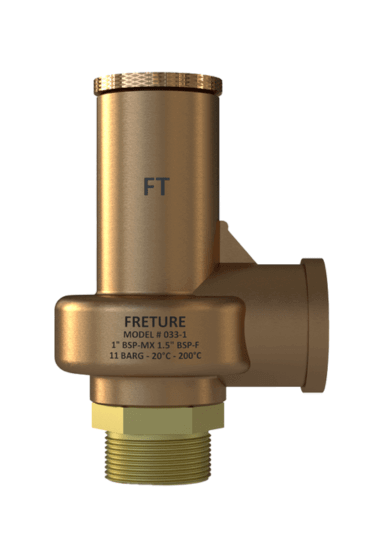

At first glance, safety relief valves might seem like simple devices, but their design and operation are anything but basic. Typically, these valves consist of a spring-loaded mechanism that remains closed under normal operating conditions. However, when the pressure exceeds the predetermined threshold, the valve opens, allowing fluid to escape until the pressure returns to safe levels.

The mechanism involves a delicate balance between the force exerted by the internal pressure and the opposing force from the spring. This equilibrium ensures that the valve opens precisely at the set pressure, providing reliable protection against overpressure events.

Applications Across Industries

Safety relief valves find applications in a myriad of industries, ranging from chemical and petrochemical plants to pharmaceutical manufacturing and power generation facilities. Any system dealing with pressurized fluids or gases necessitates the presence of these valves to mitigate the risk of catastrophic failures.

In the oil and gas sector, safety relief valves are integral components of pipelines, refineries, and offshore platforms, where they safeguard against the dangers posed by volatile substances and high-pressure environments. Similarly, in the pharmaceutical industry, these valves play a crucial role in maintaining the integrity of processes involving hazardous chemicals and sterile environments.

Ensuring Compliance and Standards

Safety is not a mere aspiration but a regulatory requirement enforced through stringent standards and codes. Organizations such as the American Society of Mechanical Engineers (ASME) and the International Organization for Standardization (ISO) lay down comprehensive guidelines for the design, installation, and maintenance of safety relief valves.

Adherence to these standards is non-negotiable for industries, ensuring that safety relief valves are properly sized, installed, and tested to perform reliably under all conditions. Regular inspections and maintenance further reinforce the effectiveness of these valves, providing an added layer of assurance against potential failures.

The Human Factor: Protecting Lives and Livelihoods

Behind every safety relief valve lies a compelling narrative of human ingenuity and resilience. These devices aren’t just pieces of metal and springs; they embody the collective effort of engineers, technicians, and safety professionals dedicated to ensuring the well-being of individuals and communities.

Consider a scenario where a malfunctioning safety relief valve leads to a catastrophic explosion in a chemical plant. The consequences extend far beyond property damage; lives are lost, families shattered, and communities scarred. It underscores the profound responsibility entrusted upon safety professionals to uphold the highest standards of diligence and competence in safeguarding against such tragedies.

Innovation and Evolution

As technology advances and industries evolve, so do safety relief valves. Manufacturers continually strive to enhance the performance, reliability, and efficiency of these critical components. From advanced materials and coatings to predictive maintenance algorithms, innovation drives continuous improvement in safety standards.

Digitalization and the Internet of Things (IoT) have also revolutionized the monitoring and management of safety relief valves. Real-time data analytics enable proactive maintenance strategies, identifying potential issues before they escalate into safety hazards. Such technological advancements exemplify the relentless pursuit of excellence in ensuring industrial safety.

Conclusion: Guardians of Industrial Safety

In the intricate tapestry of industrial processes, Safety Pressure Relief Valves stand out as silent sentinels, steadfastly guarding against the specter of overpressure disasters. Their significance transcends mere functionality, embodying a commitment to excellence, integrity, and, above all, human safety.

As industries march towards a future defined by innovation and progress, safety relief valves will remain indispensable companions, ensuring that the wheels of production turn smoothly while safeguarding the lives and livelihoods of those they serve. Let us never underestimate the profound impact of these unassuming yet indispensable devices, for they are the unsung heroes of industrial safety.

No comments:

Post a Comment