Safety is paramount in industrial operations, and one of the key components ensuring this safety is the safety relief valve. Among the various types available, bronze safety relief valves stand out for their durability, reliability, and wide range of applications. In this blog post, we'll explore the different aspects of bronze safety relief valves, including their manufacturing standards, end connections, sizes, and pressure ratings. We'll also highlight why Freture Techno is a leading manufacturer of these valves in Mumbai, India.

Types of Bronze Safety Relief Valves

Bronze safety relief valves are essential in many industries, including oil and gas, chemical processing, and power generation. These valves are designed to automatically release pressure when it exceeds a predetermined limit, preventing potential overpressure situations that could lead to equipment failure or safety hazards.

Manufacturing Standards

The quality and reliability of bronze safety relief valves are ensured by adhering to rigorous manufacturing standards. The primary standards for these valves include:

- API 520: This standard provides guidelines for the design, application, and testing of pressure-relieving systems in refineries.

- API 526: This standard specifies the requirements for flanged steel pressure relief valves.

- API 527: This standard covers the seat tightness of pressure relief valves.

- EN ISO 4126 Part 1: This standard addresses the general requirements for safety devices designed to protect against excessive pressure.

- ASME Section VIII Div. 1: This standard pertains to the construction of pressure vessels, including the requirements for pressure relief devices.

Adherence to these standards ensures that the valves perform reliably and safely under various operating conditions.

End Connection

Bronze safety relief valves come with various end connection options, making them versatile and adaptable to different system requirements. The most common end connections include:

- BSP (British Standard Pipe): A standard for pipe threading that ensures a secure and leak-proof connection.

- BSPT (British Standard Pipe Taper): Similar to BSP but with a tapered thread for a tighter fit.

- NPT (National Pipe Thread): A widely used American standard for pipe threading that ensures compatibility with various systems.

These end connection options provide flexibility in installation and integration into existing systems.

Size Range

Bronze safety relief valves are available in a wide range of sizes to accommodate different system requirements. The standard size range for these valves is from 15NB (Nominal Bore) to 200NB, allowing for application in small to large-scale operations.

Pressure Rating

The pressure rating of a safety relief valve indicates the maximum pressure it can safely handle. Bronze safety relief valves typically have a pressure rating ranging from 0.5 to 40 Barg. This broad range ensures that they can be used in various applications, from low-pressure systems to high-pressure industrial operations.

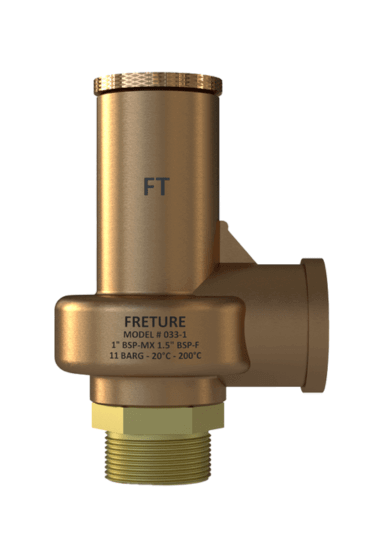

Freture Techno: Leading Bronze Safety Relief Valve Manufacturer

When it comes to high-quality bronze safety relief valves, Freture Techno stands out as a leading manufacturer in Mumbai, India. Known for their commitment to quality and innovation, Freture Techno offers a wide range of valves that meet the highest industry standards. Their products are trusted by industries across the country for their reliability, durability, and superior performance.

No comments:

Post a Comment