Chemical processing plants are dynamic environments where precision and safety are paramount. Amidst the intricate machinery and volatile substances, safety valves emerge as crucial components, providing a vital layer of protection against potential disasters. In this comprehensive guide, we explore the significance of safety valves in chemical processing plants and how they contribute to operational integrity and personnel safety.

Understanding Safety Valves: Defending Against Pressure Surges

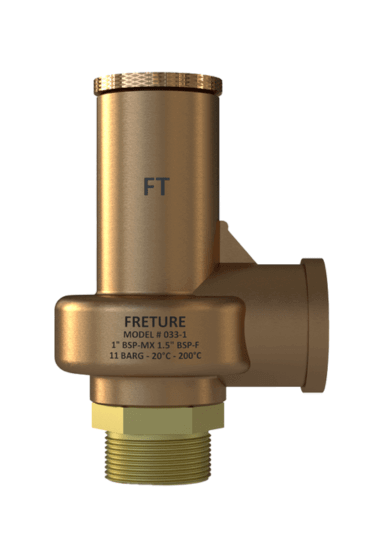

Dive into the fundamentals of safety valves, elucidating their function as pressure-relief mechanisms. Explore the different types of safety valves and their mechanisms, empowering readers to grasp their role in safeguarding against overpressure situations.

Selecting the Right Shield: Exploring Safety Valve Varieties

Delve into the diverse array of safety valves available for chemical processing plants, from pressure relief valves to rupture discs. Highlight the unique features and applications of each type, aiding plant operators in making informed decisions based on their specific requirements.

Key Features for Enhanced Protection: Optimizing Safety Valve Performance

Explore essential features to consider when choosing safety valves, such as material compatibility, capacity, and reliability. Emphasize the importance of selecting valves that can withstand corrosive chemicals and harsh operating conditions, ensuring long-term effectiveness.

Applications Across the Plant: Ensuring Safety at Every Stage

Illustrate the wide-ranging applications of safety valves throughout chemical processing plants, from reactors and distillation units to storage tanks and pipelines. Showcase real-world examples to demonstrate how safety valves play a critical role in protecting personnel, equipment, and the environment.

Advantages Beyond Compliance: Maximizing Operational Efficiency

Highlight the multifaceted benefits of safety valves, including improved operational efficiency, reduced downtime, and regulatory compliance. Showcase case studies or testimonials to illustrate how investing in quality safety valves can yield substantial returns in terms of safety and productivity.

Navigating Challenges: Mitigating Risks and Enhancing Reliability

Acknowledge potential challenges associated with safety valves, such as maintenance requirements, false activations, and sizing issues. Provide practical strategies for mitigating these risks and optimizing the performance of safety valve systems to ensure continuous protection.

Conclusion:

In conclusion, safety valves serve as indispensable guardians of chemical processing plants, providing a critical layer of defense against pressure-related hazards. By understanding the role of safety valves, selecting the appropriate type, and implementing best practices, plant operators can uphold the highest standards of safety and operational excellence in their facilities.

No comments:

Post a Comment