Safety valves play a crucial role in ensuring the integrity and safety of industrial systems, particularly in high-pressure and high-temperature environments. These applications, found in industries such as oil and gas, chemical processing, and power generation, require reliable and efficient safety solutions to prevent catastrophic failures. This article explores the significance, design considerations, and operational requirements of safety valves in such demanding conditions.

The Importance of Safety Valves

In high-pressure and high-temperature applications, safety valves serve as the last line of defense against overpressure scenarios. Their primary function is to automatically release excess pressure from systems to prevent damage to equipment and ensure operational safety. By maintaining pressure within specified limits, safety valves protect both personnel and infrastructure from potential hazards.

Design Considerations

1. Material Selection

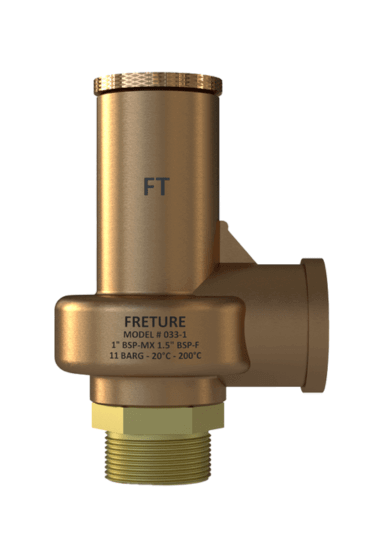

The materials used in safety valve construction are critical for withstanding extreme temperatures and pressures. Common materials include stainless steel, bronze, and special alloys, each chosen based on the specific application requirements. For high-temperature applications, materials must exhibit excellent thermal stability and resistance to corrosion.

2. Valve Sizing and Pressure Rating

Proper sizing of safety valves is essential to ensure they can handle the expected flow rates during an overpressure event. The pressure rating of the valve must match or exceed the maximum operating pressure of the system. This ensures reliable performance and compliance with safety regulations.

3. Operating Mechanism

Safety valves can be classified into several types based on their operating mechanisms, including spring-loaded, pilot-operated, and balanced bellows types. Each type has distinct advantages and suitability for different operational scenarios. For high-pressure applications, spring-loaded valves are commonly used due to their simplicity and reliability.

Operational Requirements

1. Regular Maintenance and Testing

To ensure optimal performance, safety valves in high-pressure and high-temperature applications require regular maintenance and testing. Scheduled inspections help identify potential issues such as wear, corrosion, or fouling, allowing for timely repairs or replacements.

2. Installation Considerations

The installation of safety valves must be executed with precision to ensure proper function. Factors such as orientation, location, and connection type are critical to maintaining system integrity. Valves should be installed in a manner that prevents blockage and allows for unobstructed pressure relief.

3. Compliance with Standards

Safety valves must comply with industry standards and regulations, such as API 520, API 526, and ASME Section VIII, to ensure reliability and safety. Adhering to these standards guarantees that safety valves meet stringent performance criteria necessary for high-pressure and high-temperature applications.

Applications of Safety Valves

Safety valves are extensively used across various industries, including:

- Oil and Gas: Protecting drilling rigs, refineries, and pipelines from pressure fluctuations.

- Chemical Processing: Ensuring safety in reactors, storage tanks, and transfer lines.

- Power Generation: Safeguarding boilers and steam systems from pressure surges.

In these sectors, the reliable operation of safety valves is vital for preventing accidents and maintaining continuous production.

Conclusion

Safety valves are indispensable components in high-pressure and high-temperature applications, ensuring operational safety and system integrity. By carefully considering design, material selection, and operational requirements, industries can effectively mitigate the risks associated with overpressure situations.

Freture Techno Pvt. Ltd. is a leading safety valve manufacturer in Mumbai, India, committed to providing high-quality solutions that meet the stringent demands of various industrial applications. Their expertise and dedication to safety make them a trusted partner for industries worldwide.

No comments:

Post a Comment