Safety relief valves are essential in protecting systems from overpressure, ensuring operational safety and equipment longevity. Among these, bronze safety relief valves stand out for their durability, versatility, and adherence to rigorous international standards. These valves are widely used across various industries due to their ability to handle diverse media like air, gas, and water efficiently.

This article delves into the features, specifications, and benefits of bronze safety relief valves, highlighting their compliance with standards such as ASME Section VIII Division 1, ASME B16.34, API 526, API 527, and IS 12992.

Adherence to Industry Standards

The bronze safety relief valve is meticulously designed to meet international and regional safety norms, ensuring reliability and performance. Its compliance with the following standards guarantees its suitability for demanding applications:

- ASME Section VIII Division 1: Ensures performance in pressure vessel systems.

- ASME B16.34: Specifies design, material, and testing requirements for valves.

- API 526 and API 527: Covers pressure relief valve design and seat tightness standards.

- IS 12992: Governs safety valve requirements in Indian industries.

This stringent adherence to standards ensures operational safety and regulatory compliance across industries.

|

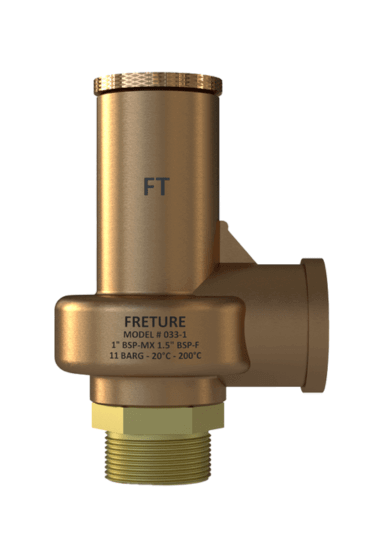

| BRONZE SPRING LOADED SAFETY VALVE |

Wide Range of Sizes and Connection Options

These valves are available in sizes ranging from 15NB to 200NB, offering flexibility to suit various system requirements. The versatile thread-end connections, including BSP, BSPT, and NPT, further enhance their adaptability to different setups.

The availability of multiple configurations simplifies integration into existing systems, making these valves an ideal choice for new installations and retrofits alike.

Operational Range

The set pressure range of 1 BAR to 35 BAR ensures effective overpressure protection in low to medium-pressure systems. Additionally, the temperature range of -20°C to 200°C enables these valves to perform reliably in both cryogenic and high-temperature applications.

This wide operational range makes these valves suitable for a variety of industries, including oil and gas, chemical processing, and water treatment plants.

Key Features

The bronze safety relief valve incorporates advanced features designed to enhance efficiency, durability, and ease of maintenance. Notable characteristics include:

Direct Spring Operation:

- Ensures precise and dependable pressure relief by responding directly to overpressure conditions.

Full Lift and Full Nozzle Design:

- Enables maximum flow capacity during operation, ensuring rapid pressure reduction.

Single Trim:

- Simplifies the design and reduces the risk of operational failure, enhancing reliability.

Fixed Blow-Down Ring:

- Facilitates consistent re-seating of the valve after pressure relief, minimizing leakage risks.

Metal/Viton Rubber Seat:

- Offers dual options for seating materials, accommodating varied application requirements and ensuring a secure seal.

Maintenance-Free Design:

- Reduces downtime and maintenance costs, making it ideal for continuous operation environments.

Applications

The versatility of bronze safety relief valves makes them suitable for a broad range of industrial applications:

Air Systems:

- Protect compressors and pipelines by relieving excess pressure efficiently.

Gas Systems:

- Ensure the safe handling of gases in chemical processing and storage applications.

Water Systems:

- Safeguard pumps, boilers, and pipelines in water treatment and distribution setups.

Advantages of Using Bronze Safety Relief Valves

Investing in bronze safety relief valves offers numerous benefits for industrial systems:

High Durability:

- Bronze construction ensures corrosion resistance and longevity in harsh environments.

Reliable Performance:

- Compliance with multiple standards and robust features deliver consistent safety and efficiency.

Versatile Design:

- Compatibility with a wide range of media and operating conditions enhances application flexibility.

Cost-Effectiveness:

- A maintenance-free design reduces operational costs, providing long-term value.

Ease of Installation:

- Thread-end connections simplify the setup process, saving time and effort.

Importance of Choosing the Right Valve

Selecting the appropriate safety relief valve is critical to ensuring system safety and performance. Factors such as pressure and temperature ratings, material compatibility, and connection type must be carefully evaluated. Bronze safety relief valves are ideal for applications where corrosion resistance, adaptability, and compliance with stringent standards are required.

Conclusion

Bronze safety relief valves provide a reliable, versatile, and cost-effective solution for overpressure protection across industries. Their adherence to international standards such as ASME Section VIII Division 1, ASME B16.34, API 526, API 527, and IS 12992, coupled with their robust features, ensures exceptional performance and durability.

With a wide range of sizes, pressure settings, and temperature compatibility, these valves are indispensable for air, gas, and water applications.

For industries seeking reliable safety relief solutions, Freture Techno Pvt. Ltd. emerges as a leading manufacturer of bronze safety relief valves in India, delivering high-quality products tailored to meet diverse industrial needs.